Compressed Air System Design

Compressed air system design. High quality compressed air is by definition 100 oil free class 0. Leak Detection Leaks in compressed air systems are a regular feature. Here are some suggestions for getting those key design items right from the start.

Air of this quality is required in medical applications the food-industry and electronic industry. If your compressed air piping design is not well done your energy costs will go up your equipment may fail production efficiencies may be reduced. Custom Industrial Compressed Air System Design.

But plant personnel are typically generalists having a broad knowledge of their field but often having little specific compressed-air-system design skills. Depending on what kind of work a shop does and how many people are using equipment there are numer- ous compressed air system options and design qualities that can make a shop efficient and safe. It is not a design guide for new or.

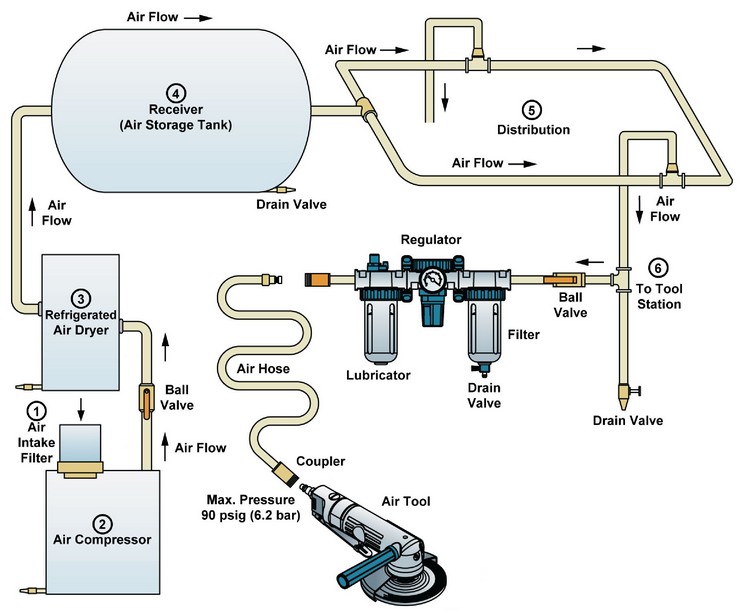

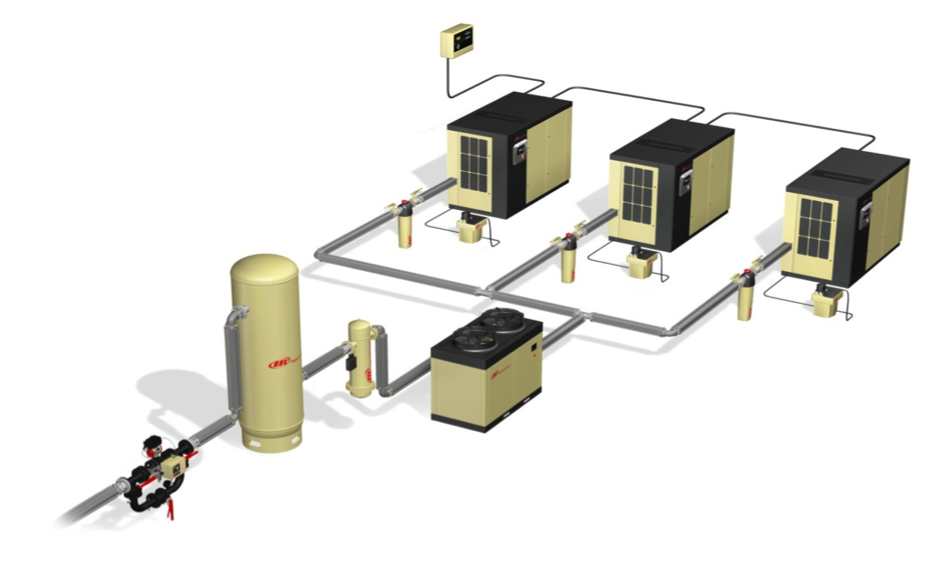

The purpose of an air compressor is to concentrate free air decrease its volume and increase its pressure. For low variation simply purchasing 2 compressors rated for 100 of the total flow is one strategy. Compressed air system design basics.

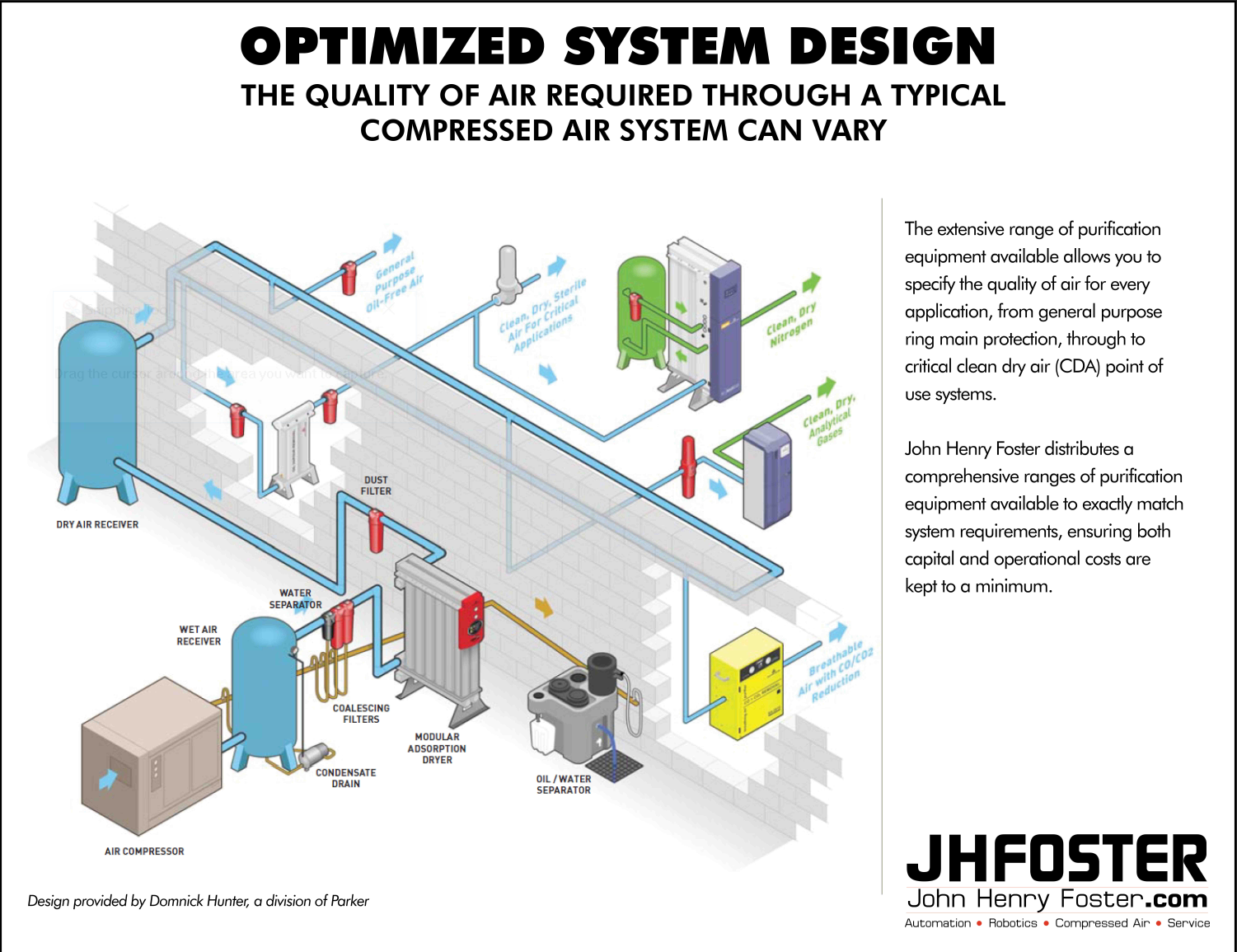

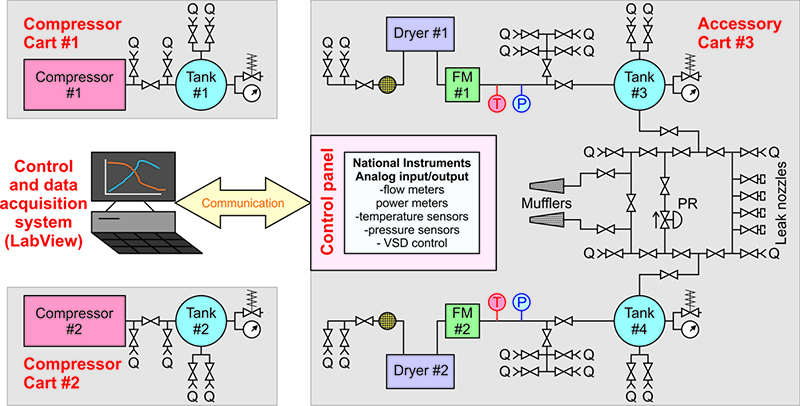

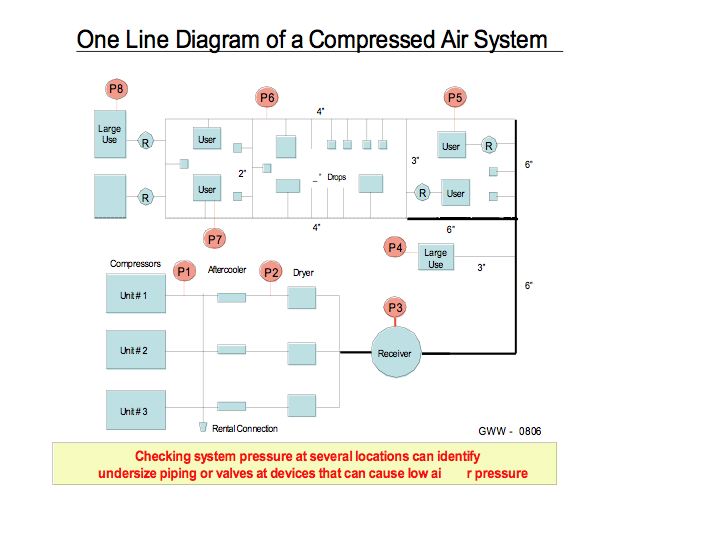

Flow meters can be inserted into compressed air piping without interrupting system production and output standard signals to a recording. And every possible problem and solution that is associated with. The ISO 85731 Standard updated in 2001 established Quality Class Numbers to be applied to different levels of contamination in compressed air systems.

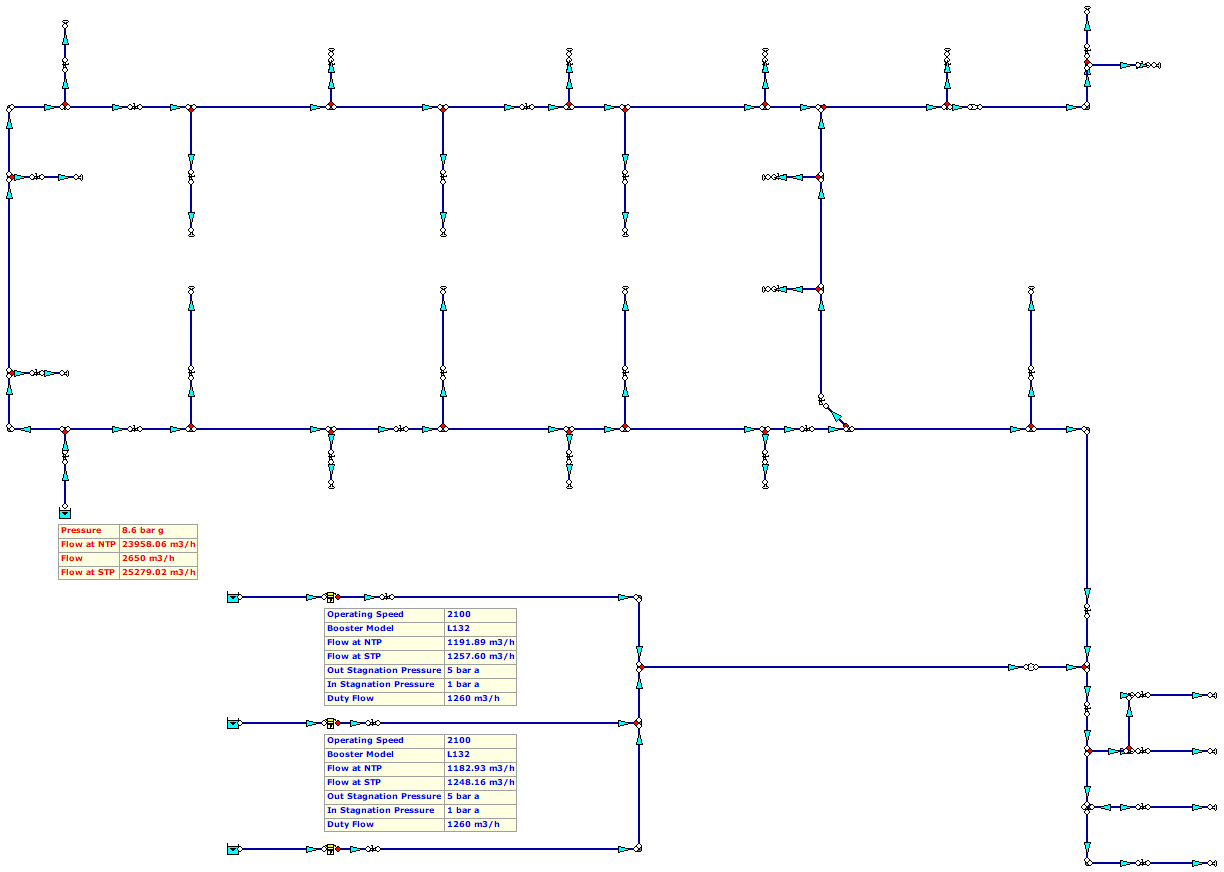

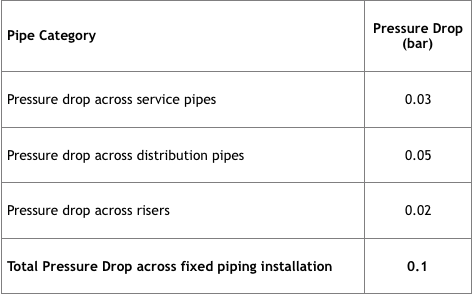

This is called standard cubic feet per minute CFM. Additional guidelines to consider when designing a compressed air system include. The energy requirements served by.

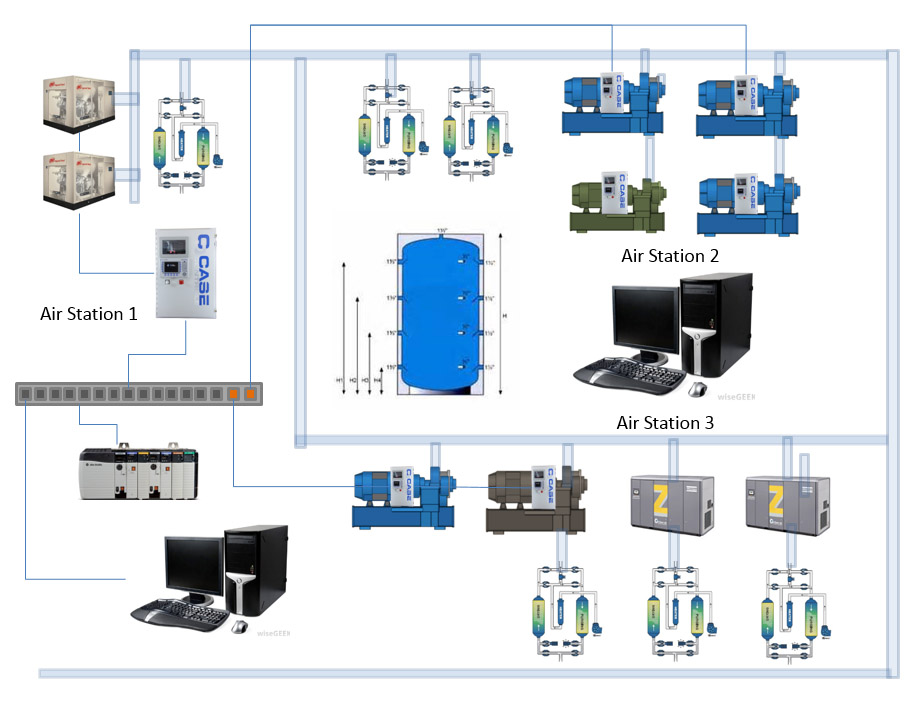

If your design work includes building management systems BMS Kaesers unit controls and Sigma Air Manager can easily tie the compressed air system into facility management systems for full remote. Careful evaluation of existing and proposed additions to the distribution system will result in.

Our systems are built using materials from established brands augmented by careful selections of the latest and greatest in monitoring technology.

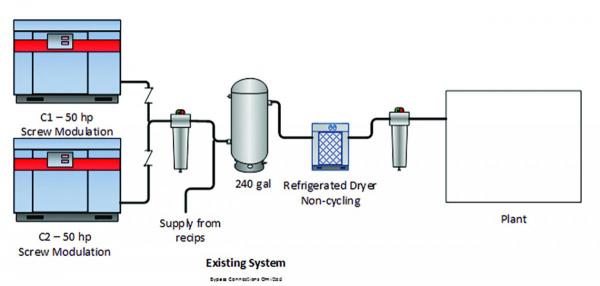

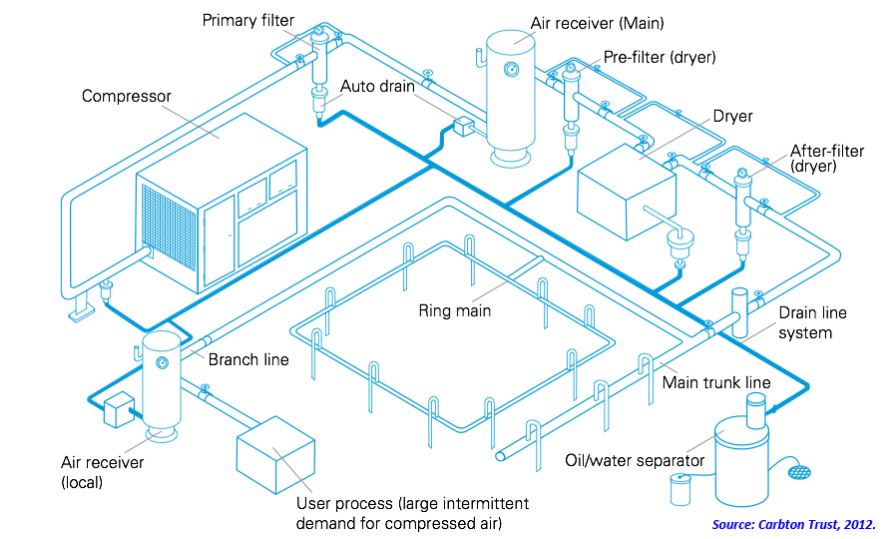

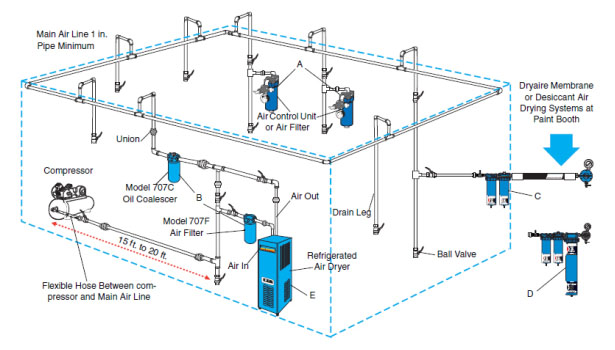

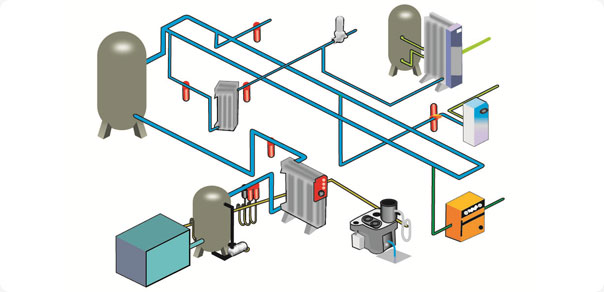

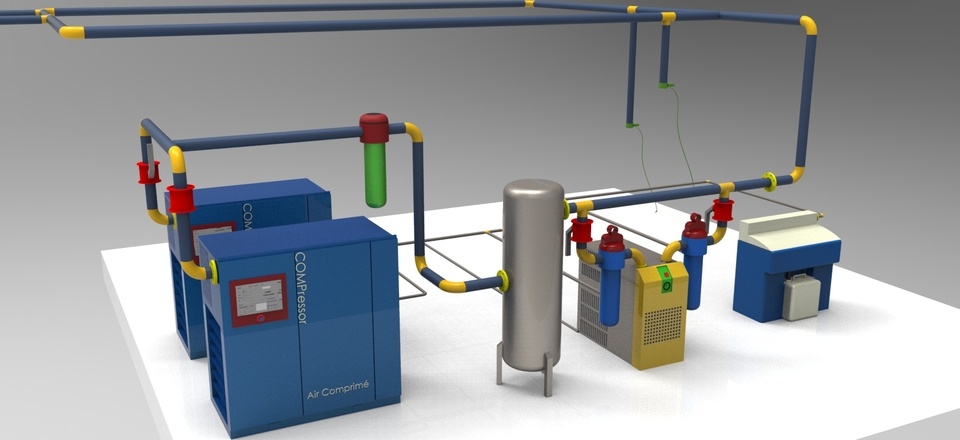

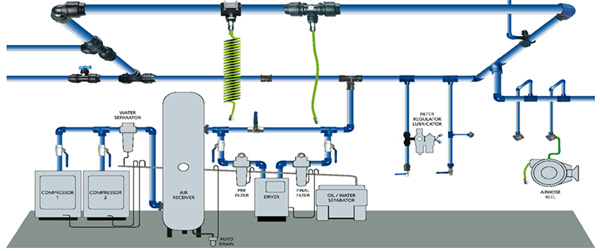

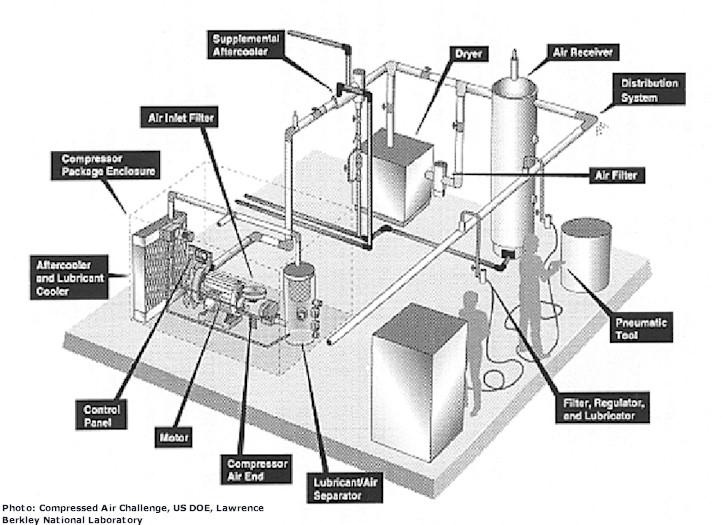

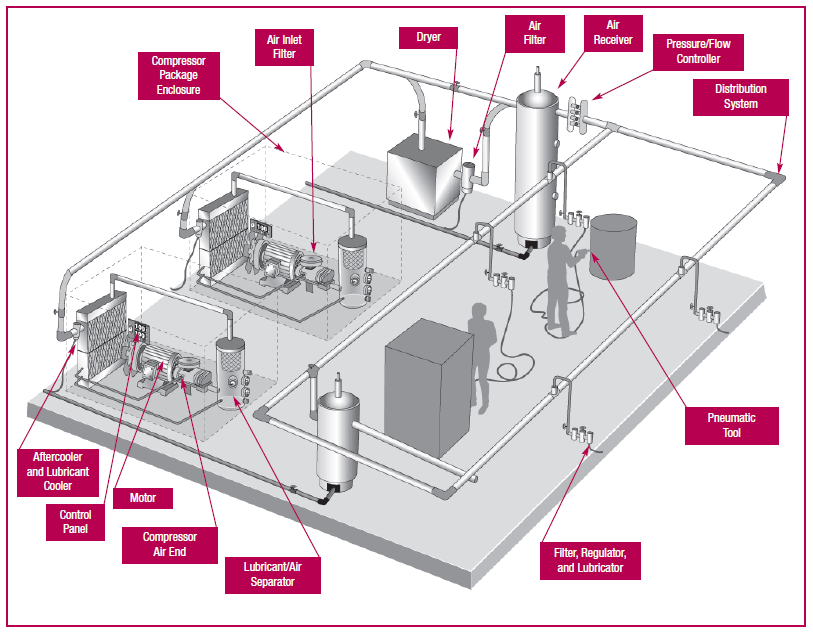

Careful evaluation of existing and proposed additions to the distribution system will result in. When it comes to your compressed air piping design and the layout of the system as a whole there are eight basic elements to consider. A compressed air system may consist essentially of one or more compressors. And every possible problem and solution that is associated with. Once total flow and variations are determined equipment selection may begin. For low variation simply purchasing 2 compressors rated for 100 of the total flow is one strategy. Compressed air system as well as things to think about as you begin or continue to optimize your compressed air system for peak performance. At Airtec we have years of experience designing reliable compressed air systems with a deliberate focus on efficiency. The purpose of an air compressor is to concentrate free air decrease its volume and increase its pressure.

Compressed air is measured on the basis of the volume used per unit time cubic feet per minute - CFM at a given pressure psi bar. Our independence is key to our success we are not encumbered by the constraints of a typical compressor dealer we design each system with an open mind and scour the market for equipment that best suits our clients needs. Compressed air is measured on the basis of the volume used per unit time cubic feet per minute - CFM at a given pressure psi bar. Air dryer and filtration selection. Leak Detection Leaks in compressed air systems are a regular feature. But plant personnel are typically generalists having a broad knowledge of their field but often having little specific compressed-air-system design skills. Depending on what kind of work a shop does and how many people are using equipment there are numer- ous compressed air system options and design qualities that can make a shop efficient and safe.

Post a Comment for "Compressed Air System Design"